|

| photo courtesy of: Wikimedia Commons |

The corrugated cardboard is separated and then bundled with equipment such as the QCR balers. Baling the cardboard allows for efficient and space-saving transportation, saving valuable resources.

Once the cardboard is put into a bale, it is sent back to the paper mill to be reprocessed.

|

| photo courtesy of: Chris 73 / Wikimedia Commons |

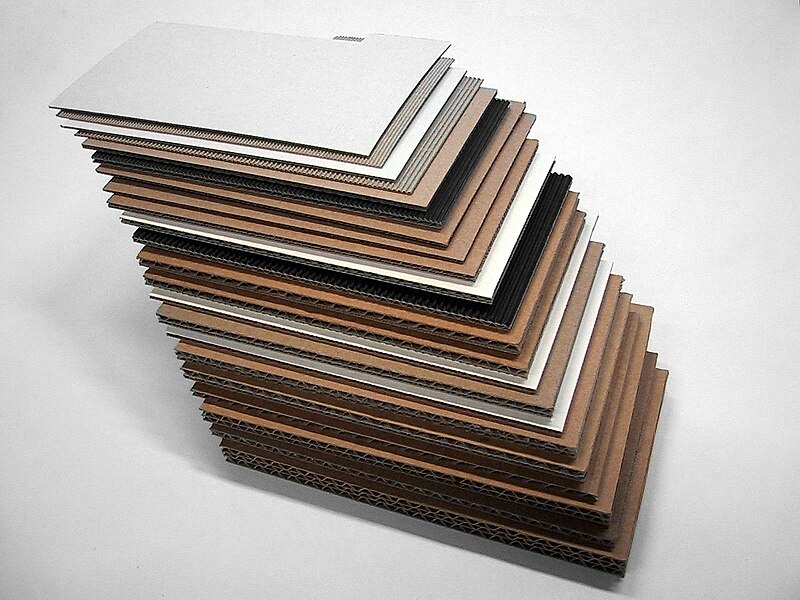

The fiber solution then is pressed between rollers to remove additional water. It heads to a dryer where it is rolled onto spools weighing up to 60 tons. Those spools of pressed fiber then are separated into individual rolls weighing up to 3 tons, and the paper rolls are ready to be turned into the 3 layer product we know as corrugated cardboard.

We'd like to thank today's post sponsor for ongoing work towards

environmentally responsible waste management and recycling.

environmentally responsible waste management and recycling.

No comments :

Post a Comment